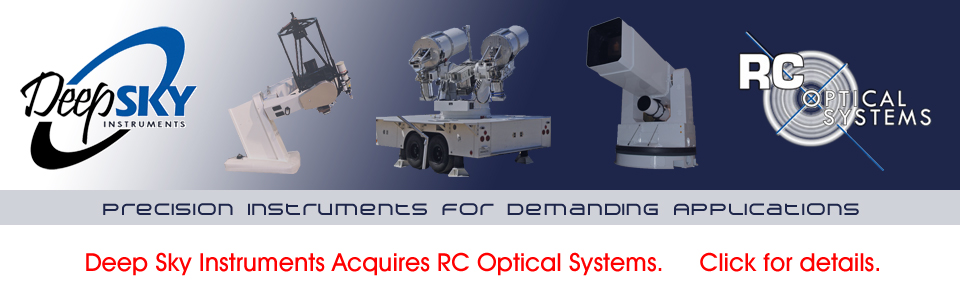

RCOS "Professional Series" Equatorial Fork Mounts

Specifically designed for the RC Optical Systems 20RC and 24RC.

| Product Review / Reference Information | Author | Date | File |

| 24RC and Professional Series Equatorial Fork Mount | Mike Rice | January 2007 | PDF - 397KB |

Fork Specifications:

- CAD designed, engineered and modeled.

- 100% CNC machined.

- Fabricated (and then welded) 6061 aluminum.

- 34 inch span between fork arms.

- 32.5 inch "swing through" clearance from center of rotation.

- Bearing axis is line bored after final assembly.

- Byer's 15 inch Research Grade Dec gear.

Polar Axis Specifications:

- CAD designed, engineered and modeled.

- 100% CNC Machined.

- Payload Capacity - 1000+ pounds.

- Major Axis Bearing - 16 inch O.D.

- Fabricated 7075 aluminum.

- Stainless Steel polar shaft.

- Bearing axis is line bored after final assembly.

- Precision polar alignment adjustments in Altitude and Azimuth.

- Byer's 20 inch Research Grade RA gear.

- The polar axle is a 9" O.D. cast 303 Stainless Steel tube with an 18" diameter 7075 aluminum hub pressed into place. The entire assembly is then machined (in a lathe) as one piece.

- The finished Polar Axle alone weights 175 pounds.

Software Bisque Servo Driven Professional Version TCS MKS-4000 Control System:

- Brushless DC-servo motors ensure long life and smooth operation.

- Field upgradeable flash RAM permits easy software updates.

- Fast slew speeds and consistent torque at all slew rates. A maximum rate of three degrees per second in right ascension and three degrees per second in declination gets you to the object, fast.

- Virtually unlimited selection of tracking and slew rate control.

- AutoHome™ capability (to better than one arc second) with built-in sensor circuitry on each axis ensure that the mount always knows its orientation (after a one-time initialization), even after power failure.

- Software controlled "hard limits" prevent the mount from tracking or slewing into itself.

- User-defined parameters can be stored to onboard flash RAM.

- Numerous safety features critical to remote operation including current-limit protection, encoder-error limits, acceleration ramping, and user-definable maximum slew speeds.

- Joystick or PC software control.

- Programmable and updateable Periodic Error Correction.

- Control system can track at true lunar, solar, minor planet or comet, NEO or LEO satellite rates, or at almost any user-defined rate (when used with TheSky). No other commercially available control system can make this claim.

- TheSky has been updated to provide many new capabilities that were previously not possible. Some examples of these new features include: display a graph of the periodic error of the worm gear; track a low-earth satellite by clicking on the object on the Sky Display.